Master Data Points

It is recommended to use master data points wherever several devices of the same type are modeled through data points. Even if we only have a pump in our example, we still need two level measurements and three valves that should be configured. In a real plant, hundreds of devices of a device type are often used. Therefore, the following steps are required.

Instead of configuring the controlfunctionalities (configs) for each element of every DP individually, you can select and configure the configs for the whole device class at once.

First you have to create the data structure for the further data point types. Create the structures for the data point types GS_LEVEL and GS_VALVE corresponding to the following tree views (see the chapter Modeling of Data Point Types).

After this, select the data point type GS_LEVEL from the tree view and select the "Create master data point" entry of the context menu [rightMouseClick]. The master data point will now be created automatically: the naming corresponds to the data point type, however the prefix "_mp_“ (for a master data point) is added.

The master data point is a unit with the data point type. For a master data point, the configs are specified for the instances, whereas the data point type specifies the structure, naming and data types for all instances. There are properties that are configured consistent fixed for all instances at the master data point. Other properties have to be set different depending on the device. Therefore, there are different types of configs for master data points. Since configs of master data points already contain specific settings or are able to represent combinations of several configs, they are called "PowerConfigs" in order to differentiate them from the normal configs.

WinCC OA can be used with individually created data point instances and therefore without a master data point, as well as with predominantly similar data point instances (with a master data point). If you delete an existing master data point of a data point type, the type irrevocably loses a part of its object properties - if necessary the existing data points (instances) still work but are separated from the inheritance. Therefore, always work with master data points.

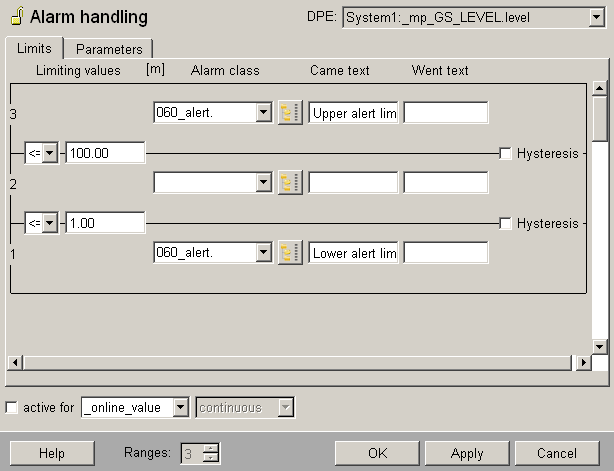

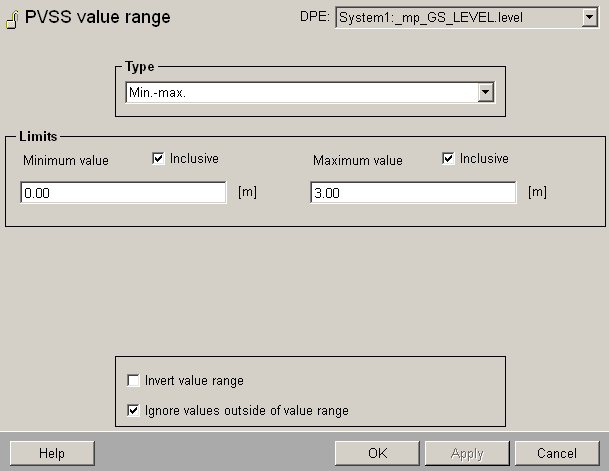

In the next step you specify a value range monitoring as well as an analog alert handling for all level measurements of the data type GS_LEVEL . Therefore, open the master data point and select the following configs on the leaf element _mp_GS_LEVEL.level [right mouse click] > Add PowerConfig.

In the following figure the PowerConfig "WinCC OA Value range" was selected for the value range. This is necessary since the tanks and reservoirs always have different heights and cubic capacities. Therefore, you have to enter the limit values for the level individually for each device (data point/instance). The range limits which are configured here, are just a one.time preconfiguration.

The setting "WinCC OA value range" - fixed would have meant that all .level data point elements of data point type GS_LEVEL have numerically the exact same value range. For example, this would be used for a percentage value of a flap or a standardized rotation speed.

You can also define the alert handling - make the settings as shown in the figure above. By selecting an alert handling with three ranges, it's possible to set different limit values for higher and lower alerts for each data point later.

Fixed would have meant that you can configure an arbitrary alert handling for a master data point later and this would be applied identically to each .level element for each data point of type GS_LEVEL. This means the same limit values would be monitored for each level and an exceedance would always cause an alert of the same priority.

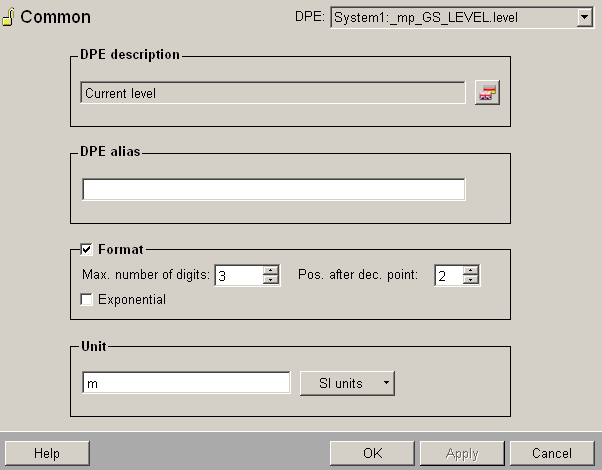

In order to set a meaningful formatting and unit for all future level measurements, add a third power config "Var: Description: Fixed: Unit (and Format)" as shown in the figures above. This means that you can configure a different description for each data point (for each device) but the unit and the format for the number representation will be inherited from the setting of the master data point.

The figures above show the dialog for the power config selection after completing the settings - the selected option of the PowerConfig is shown behind the type of the PowerConfig. Confirm with OK. Confirm also the displayed hint that you have to configure these PowerConfigs subsequently.

Apply the settings as shown in the following figures in your project.

After completing the entries with OK in the last parameter dialog, you have to apply the settings. Click on Yes in the confirmation dialog to apply the settings.

The settings are also applied for already existing data points. Therefore, changes for a master data point can be applied to the instance data points.

Now the next step would be creating instance data points for the tank 1 and for the tank 2. Subsequently the properties that are "variable adjustable for the instance" would be configured. These steps are described detailed in the chapters Creating data points with the database editor PARA and Configuration of the PowerConfig Settings for Data Points. First, you will, however, prepare also the last data point type GS_VALVE using a master data point.

Proceed correspondingly when configuring the PowerConfigs for the data point type GS_VALVE.

-

Create a master data point of type GS_VALVE using the context menu [rightMouseClick] > create master data point

-

Open the tree view so that all elements of the master data point _mp_GS_VALVE will be shown.

-

Add a powerConfig "WinCC OA value range "Fixed" to the _mp_GS_VALVE.state.position. element.

-

Add also a PowerConfig "Description, Unit, (Format)" > "Var:Description;Fixed:Unit (and Format)" to the same element.

-

Configure the value range with 0...100, the format with 4 digits before and 1 digit after the decimal point (corresponds to ####.#) and enter "%" for the unit.

-

Repeat the steps from 3 to 5 for the element _mp_GS_VALVE.cmd.position.

-

Add the powerConfig "Alarm andling" > "Fixed" to the element _mp_GS_VALVE.alarm

-

Configure this binary alert handling as follows: alert class = 060_alert, OK range is 0 or FALSE, alert text is "Valve failure". Select "_online.._value“ as source for the alert handling and activate it through the check box.

You can also configure PowerConfigs yourself - you could, for example, define a PowerConfig to automatically calculate all peripheral addresses for all devices (data points) on the basis of instance names/numbers. You can also configure PowerConfigs that summarize several "common" configs into one logical config. For more information on master data points and PowerConfigs, see chapter Mass configuration, Basics in the online help.