S7 Driver

The WinCC OA S7 driver is a native driver for connection to the periphery with Siemens S7 PLCs.

The driver can communicate with S7-300, S7-400 and S7-1200 devices. The native S7 driver can be used under Windows and Linux for

-

Sending data to the PLC.

-

Polling data from the PLC.

-

Receiving spontaneous data from the PLC. For this purpose you must use the extension TSPP (Time Stamped Push Protocol).

-

Receiving and acknowledging S7 alarms

The protocol used for this driver is the so called ”S7 messaging” the telegrams are transported via TCP/IP. S7 messaging is the protocol that Siemens applications also use for communication. As opposed to the Fetch/Write protocol, for example, it is possible to encode data for several data blocks in one telegram.

Considering redundancy with WinCC OA and the periphery the following cases can be covered with the S7 driver in WinCC OA:

-

WinCC OA can be redundant.

-

Each WinCC OA system can have one or more network cards for the communication with the PLCs.

-

Each WinCC OA system can have one or two connections to each PLC.

-

Each WinCC OA system can communicate with two redundant PLCs (either in one redundant PLC or two PLCs).

Client/Server and Master/Slave

In normal operation the S7 driver will be the master in the communication as usual for a SCADA system. This means that the communication requests are sent by the S7 driver.

The S7 driver also supports the Slave mode for the TSPP extension (in this case it is also possible to receive spontaneous data from the PLC). The establishment of the TCP/IP connection for a TSPP connection is also done by the driver.

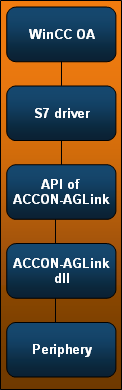

Layer model

The S7 driver in WinCC OA was implemented with ACCON-AGLink, a toolkit from Deltalogic. The programmed API of ACCON-AGLink and the DLL from this toolkit is the interface between WinCC OA / S7 driver and the periphery / S7 PLCs. The ACCON-AGLink provides the following functions:

-

Configuration of the connections

-

Establish / close the connections to the PLCs

-

Send data to the PLCs

-

Poll data from the PLCs

-

Alive check for the used connections

For the communication with a S7 PLC the S7 messaging protocol via TCP/IP is used. The advantages of this protocol are:

-

Mixed data (data with different data types) can be sent in one telegram

-

Data in different DBs can be sent in one telegram

The design of the connection to the periphery via ACCON-AGLink consists of the following layers: